USHA Yarns recycles fabric waste into yarn, Pre consumer pre dyed garment cutting waste, Polyester made from recycled PET bottles

From the USHA Yarns site.

“Let’s face it: the textile and fashion industries have a huge environmental footprint. At Usha Yarns, we believe that what is good for the planet is also good for your business. By using pre-consumer pre-dyed garment cutting waste and polyester made from recycled PET bottles to produce our high quality yarns, we make a sustainable product with a significantly reduced environmental footprint at a lower price.

As the consumer demand for eco-friendly products has increased, manufacturers are discovering the competitive advantage that using recycled materials in production can have for their brand and for their bottom line.”

“We found our inspiration in Steve Labonte’s words; “Recycling is a concern both human and divine”.

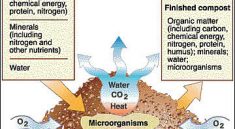

Which means that everything on Earth is connected.Whether it is water, air, soil, nutrients, minerals, gases, or microorganisms, nature has been recycling everything in a precise ecological balance that has been occurring for all of our planet’s history. These processes ensure that all of life on Earth is sustained, and humanity has an important role to play in being the caretakers of our planet.

As citizens of Planet Earth, we at Usha Yarns understand that recycling waste and creating a closed loop industrial system is a key component of having a sustainable world and a sustainable business aligned us with nature.”

“RECYCLED KNITTING YARN

Our regenerated knitting yarns are cotton rich and available in a wide range of colours in 72 shades. They are available in coarse and fine counts, and in single and double ply options.

UYL knitting yarns are available in different composition of blends, including: Cotton, Cotton and Polyester, Cotton and Viscose, Cotton, Polyester, and Viscose, Cotton, Polyester, and Wool Blend.

Our knitting yarns are suitable for running on: circular knitting machines for making single jersey, fleece, french terry, pique knit, and rib; interlock knitting machines as well as flat knitting machines.

These yarns are ideal for the production of hosieries or garments items such as tees, hoodies, lowers, and sweatshirts, terry towels, thermal wear, sweaters, and socks.”

“TECHNOLOGY

Usha Yarn Limited’s modern production facilities span across our 16 acre manufacturing campus located in Derbassi. Our production facilities are equipped withthe most modern spinning machines made by Rieter, Truetschler, Oerlikon, and Schlafhorst.

More than 650 tons of regenerated yarns are produced by our plants each month, with every single batch undergoing a strict quality control evaluation. This thorough process ensures that each product that leaves our production line meets global quality parameter standards and your complete satisfaction.

Our unique product offerings such as best color matching without lot variation and recycled yarns for producing quality hosiery/knitting garmentsset us apart from our competitors in this industry. With Usha Yarns, you can be sure that you’re always getting the best.”

Read more: